How Does Work The Solar Panel Recycling?

The first generation of solar PV panels has already worn-out. A solution for pollution free disposal had to be found.

If disposal of solar PV panels is not carried out correctly, then the positive impact they have on the environment, is destroyed.To avoid this, there are electronic waste directives (e.g., the Waste Electrical and Electronic Equipment Directive in EU, Electronic waste in the United States, etc.).

These establish that solar module manufacturers are obliged to take back worn-out solar PV panels for free and to recycle them.

What does a solar module consist of?

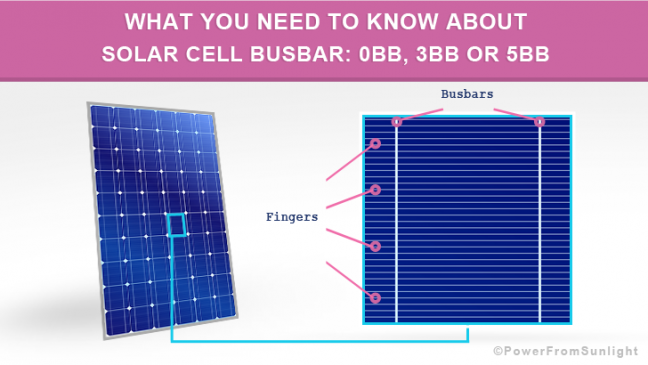

A solar module mostly consists of a glass pane, which serves as a protection against weather conditions and dirt, a transparent plastic layer, and the underlying photovoltaic solar cells.

The back lamination takes place through a weatherproof composite plastic foil, and the entire solar module is fixed onto an aluminum frame. A diode ensures that the solar electricity only passes through in one direction and acts in the other direction as an insulator.

Via connection cables, the power produced is conducted through an inverter, which transforms the collected DC voltage into AC voltage energy. Then, the electricity can be used in the household, stored in batteries or fed into the utility grid.

The most common material used in the solar PV panels is the silicon. The semiconductor is subdivided into monocrystalline and polycrystalline silicon, which is used for the so-called thick-film modules. Thin-film modules often have amorphous silicon or Cadmium Teluride cells.

How does solar panel recycling work?

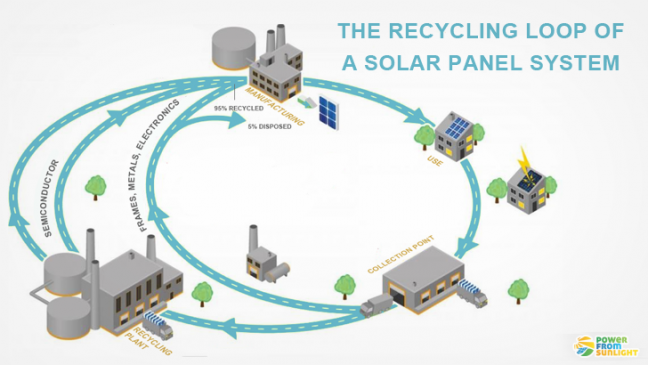

There are two options: The PV module is dismantled and collected by the manufacturer, or you search for the nearest collection point.

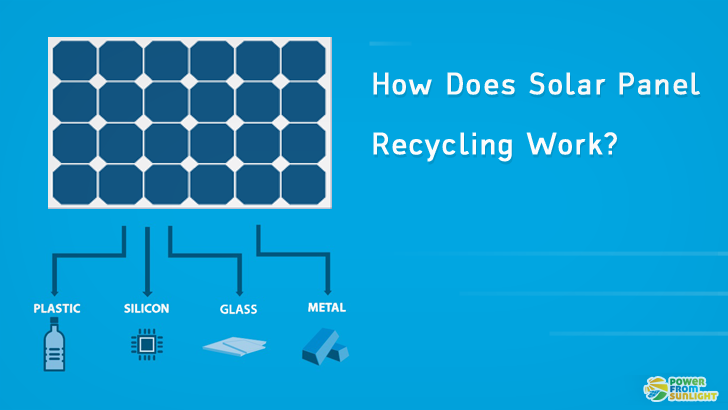

First, the old solar PV panels are separated from its aluminum frame, cables, and the electronic parts. These can be recycled directly, and then they are reduced to small pieces.

After that, depending on the solar cell type, the separation of semiconductor materials takes place from the other materials. In the case of silicon solar cells, a thermochemical separation called pyrolysis takes place. In this way, the plastic burns and the semiconductor are separated from the glass, which can be directly recycled. The silicon remains in a metalliferous liquid.

Through the so-called precipitation by pH, in which a defined pH (pH is a numeric scale used to specify the acidity or basicity of an aqueous solution) has artificially created to deposit the solids in the liquid. With the aid of other chemical processes, the deposited material is filtered, compressed and can be used to produce new photovoltaic solar cells.

All in all, about 95% of solar module materials are recyclable. At the same time, the production of a solar PV panel from recycled material costs only 30% of energy, which would be required for the production of a new solar module. So, solar panel recycling is worth it.

The future of solar panel recycling

Research is still being carried out to improve the solar panel recycling processes so that costs can be saved and the percentage of the recycled components can be increased.

For example, the Fraunhofer Institute in Germany is working to develop solar PV panels which can be on-site opened as well as closed.

In this way, worn-out photovoltaic solar cells can be replaced without any exchange of other still good solar panel components such as metals, frame or electronics.