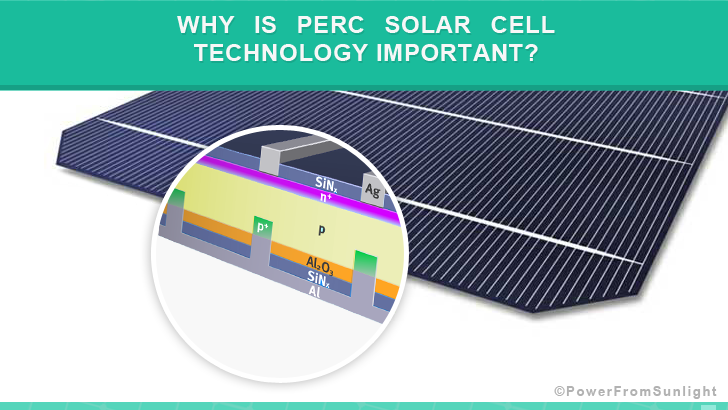

Why Is PERC Solar Cell Technology Important?

In order to increase the solar panel efficiency, manufacturers use a new technology called PERC Solar Cell Technology.

This article will give you the key information about this technology in a straightforward way.

What is a PERC solar cell?

PERC stands for Passivated Emitter and Rear Cell or Passivated Emitter and Rear Contact.

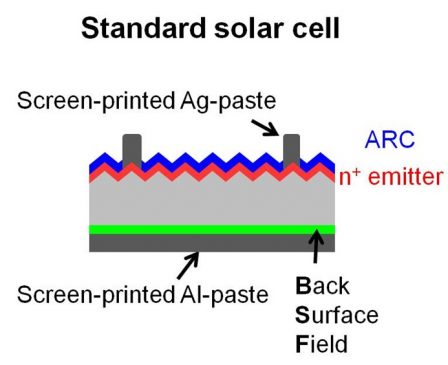

The standard solar cell architecture

The standard solar cell architecture that has been in use for three decades is the following:

From front to the rear side of the solar photovoltaic cell:

- Silver front contacts

- Anti-Reflective Coating (ARC)

- Silicon wafers that form the P-N junction

- Aluminum Back Surface Field (Al-BSF) and

- Aluminum metallization layer

(Source:Institute for Solar Energy Research Hamelin (ISFH))

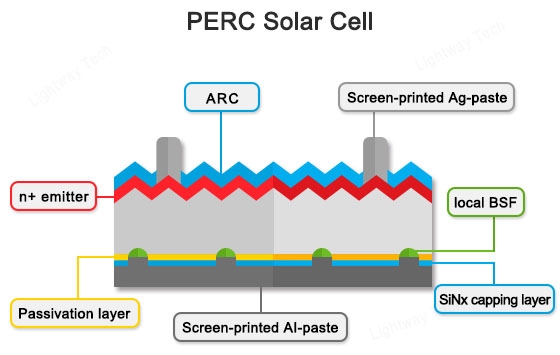

How is the PERC solar cell made?

PERC solar cell technology is based on a change in the design of the rear of the solar photovoltaic cell, which improves the light capture falling on its surface.

In order to create a PERC solar cell, two steps are required during the solar cell manufacturing process:

- A dielectric passivation layer is added to the back of the solar photovoltaic cell.

- Lasers or chemicals are used to open the rear passivation stack and create tiny holes in the film to absorb more light.

Solar panel manufacturers can approach the two steps in different ways.

The PERC solar cell has the following architecture (From front to the rear side of the solar photovoltaic cell):

- Silver front contacts

- Anti-Reflective Coating (ARC)

- Silicon wafers that form the P-N junction

- Local Aluminum Back Surface Field (Al-BSF)

- Passivation layer

- SiNx Capping Layer and

- Aluminum metallization layer

(Source: https://www.enfsolar.com)

What are the advantages of the PERC solar cell technology?

The PERC solar cell technology leads to:

- The electron recombination is reduced significantly

- More light is absorbed; and

- Higher internal reflectivity is experienced.

Not all sunlight is absorbed through non-PERC solar cells, but with a dielectric layer on the backside of a PERC solar cell, unabsorbed sunlight is reflected by the additional layer back to the solar photovoltaic cell for a second absorption attempt.

This process enables solar panel manufacturers to achieve higher efficiencies than with conventional solar cells.

Besides, there are minimal modifications between the existing solar cell manufacturing and the PERC solar cell technology lines, which makes a move to this technology more straightforward and cost-effective.

PERC solar panels have a higher energy density per square meter and feature an improved performance under low light conditions and high temperatures.

Therefore, designers can use fewer PV solar panels to achieve total output goals or they can maximize energy output if space is not a premium. It enables designers to be more flexible and responsive to project objectives.